- TOP

- Four Advantages of Factory Rebar Processing

Why we believe factory rebar fabrication is an efficient method?

In 1981, approximately 80% of the rebars in Japan were processed on-sites. But did you know by 2014, about 95% have been processed in factories? The reason for this change in the rebar processing method from on-sites to factory is the rapid increase in construction due to economic growth, which has triggered problems such as rising labor costs, labor shortage, and difficulty in securing space. With the remarkable economic growth, your country is expected to experience one of these issues. So why not prepare for it now? Please read the following four points to understand about rebar fabrication at factories.

1. Resolves labor shortage issue and

increases productivity per worker

On-site Fabrication

Factory Fabrication

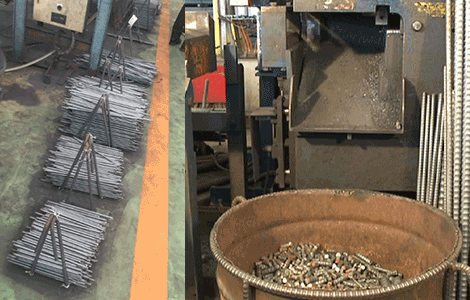

2. Reduces material waste and

establishes eco-friendly processing

Reinforcing bar material loss at construction sites is 10% or more, but it can be reduced to 3% or less at factories.

Consequently, the environmental burden can also be reduced, because 0.53 tons of CO2 is generated in recycling 1 ton of rebar scrap into rebar.

On-site Fabrication

Factory Fabrication

3. Meets strict accuracy requirements and

prevents human processing errors

Thus, uniformly aligned products can be processed, which improve the workability of assembly and installation. This also leads to the improvement of accuracy of the completed building and infrastructure.

Precast concrete products and government projects often require strict precision, and our products can confidently meet the requirements.

Infrastructure with guaranteed quality provided by our products can serve as the foundation in your countries, inconspicuously supporting your daily life.

On-site Fabrication

Factory Fabrication

4. Secures safe working space and

prevents construction-/-delivery delays

In addition, by properly securing a space, which if often not possible in on-site processing, and using an overhead crane, a safe environment is ensured for operators.

On-site Fabrication

Factory Fabrication

[ close ]