Fully automated concrete products made possible

by PROGRESS Group's innovative solutions

From BIM data import to formwork, reinforcing bars, concrete, and production management, you can rely on the Carousel System!

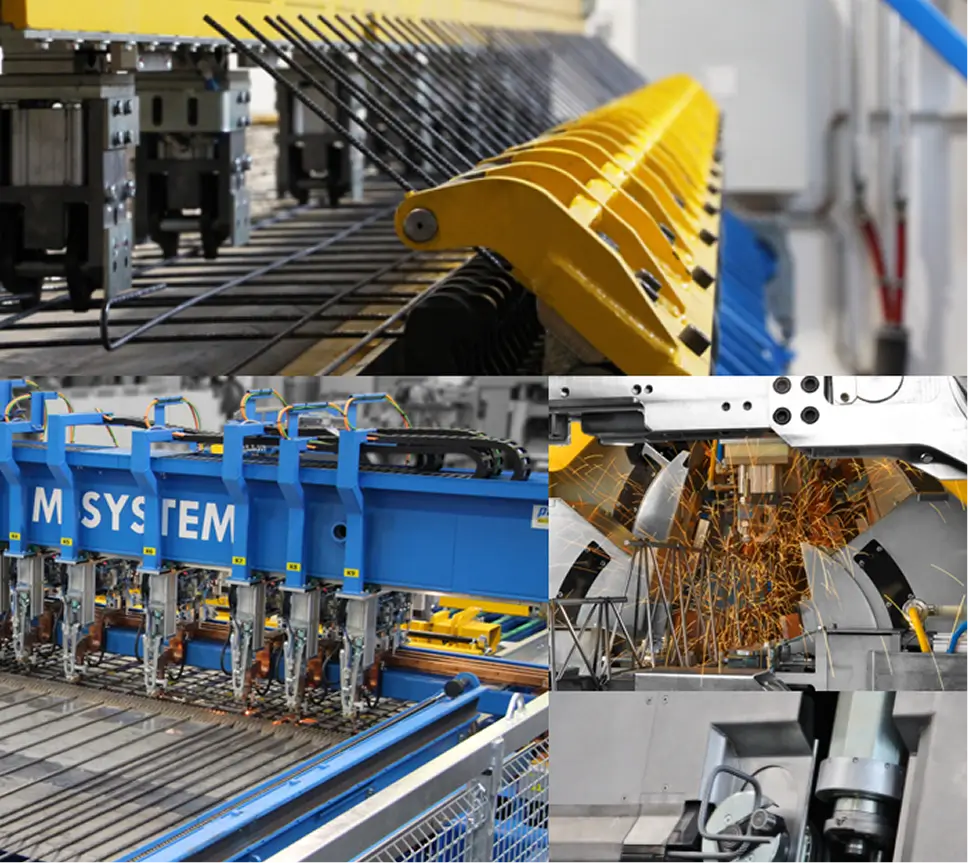

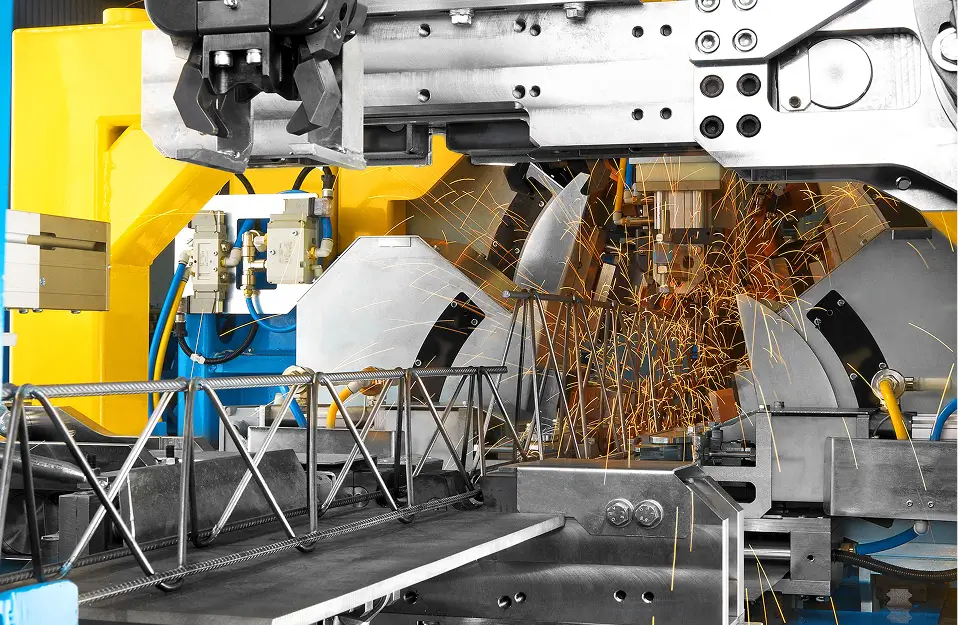

Automation of steel bar processing

The company develops and produces:

automatic mesh welding machines and mesh bending machines from coil

automatic straightening, cutting and bending machines for flexible production including 3D shapes

automatic lattice girder and cage welding machines

Automation of concrete manufacturing

Digital Solutions

About PROGRESS GROUP

Full range supplier of concrete product manufacturing equipment, headquartered in Brixen, Italy, founded in 1961.

PROGRESS GROUP realizes machines, systems and software for precast concrete plants. Building with precast concrete elements improves living conditions for people all over the world. Our technology creates attractive workplaces and environmentally friendly, durable building systems for high-quality living and working areas.

The company has its own precast plant at its head office, constructed with their own precast technology. In recent years, the company has also established Green Code, a set of sustainable building guidelines and a licence system for precast concrete product manufacturers.

Progress Group, what we have?

CAROUSEL PLANTS

REINFORCEMENT TECHNOLOGY

STATIONARY PRODUCTION

PRODUCTION ON BEDS

SOFTWARE

3D PRINTER

Carousel Systems

An automated production line for floor slabs, half-slabs and walls, where products are produced on production pallets that circulate through the plant; based on BIM data, human manual work is greatly reduced, from formwork installation, mesh placement, latticework placement, concrete placement, curing and demoulding.

Plotters, insert placers and laser projectors also streamline the human works.

Mesh Automatic Welding Machine/Mesh Automatic Bending Machine

The welding gun automatically determines the pitch, greatly reducing setup time. Even meshes with openings or special shapes can be automatically manufactured based on simple CAD data. From automatic feeding to automatic processing and automatic removal, complete automation improves productivity.

We provide optimal proposals based on customer interviews for general construction, residential foundations, and concrete products.

3D Printing System

WORLD‘S LARGEST 3D POWDER BED PRINTING SYSTEMS FOR CONCRETE

The newly developed large-format 3D printers are robust printing systems suitable for a wide range of applications and materials. Thanks to 3D powder bed technology, practically all geometric shapes can be printed without restrictions. The system design with build boxes that are alternately moved into the printer enables permanent (24/7) printing.

CASE STUDY

This machine is mainly used for cutting and bending D10 to D16 coil rebar. Straightening is automated via a touch panel, and it is also possible to automatically switch between rebar diameters (optional). It can also process labor-intensive 3D shapes such as stirrups.

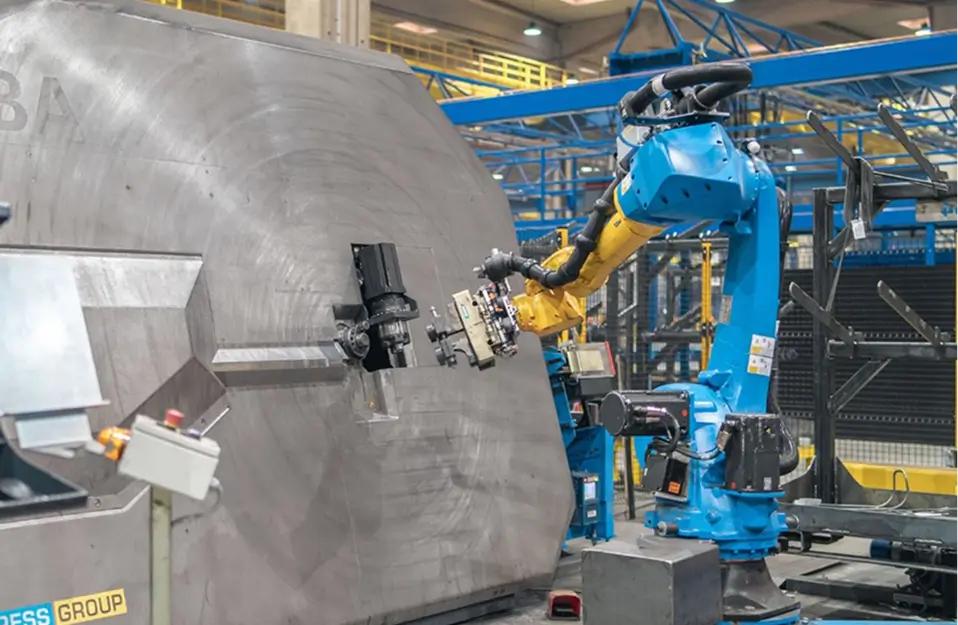

Automatic Lattice Girder Welding Machine - Vers

We introduced the first machine outside Europe in 2019. The Versa facilitates flexible-, just-in-time production of lattice girders from coil. Its particular feature is the fully automatic height and diameter changeover during production, which makes it possible to manufacture each product exactly to measure and without time-wasting retrofitting.

Others

Industry Solutions Business Unit (IS Business Unit)

Business Overview and Mission

Industry Solutions Business Unit (IS Business Unit) is a specialized department that promotes automation and digitization in the Japanese construction industry.

Utilizing the advanced technology and software of PROGRESS GROUP, we support labor saving and productivity improvement through precast construction methods.

Let’s build the future of construction together with innovative solutions!